Konjac & Konjac Flour, Gum, and Glucomannan: Uses, Health benefits

Konjac | Flour | Gum | Glucomannan | Uses | Health benefits | Safety

Konjac gum and konjac glucomannan are two water-soluble hydrocolloids that can be used as a thickener, stabilizer, gelling agent, film former and fat replacer in food, with the European food additive number E425(i) and E425(ii), respectively.

The difference between these two ingredients is mainly the purity of glucomannan in them. Glucomannan is dietary fiber and the main functional component in konjac flour. This content is required ≥ 75% in konjac gum, while needed more than 95% in konjac glucomannan.

What is Konjac?

Konjac, a traditional agricultural food with a history of 1500 years in both China and Japan. It is the tuber (root) of the perennial plant of Amorphophallus konjac.

Moisture

Moisture has a great influence on the quality of dried konjac flour. Fresh konjac tubers have a high water content (80%-85%), so it is easily moldy, spoiled and cannot be stored for a long time.

Therefore, in order to prolong shelf life, the konjac is usually processed into dried slices or chips to reduce the water content (generally about 15%) after harvest.

SO2

Konjac slices/chips are prone to browning during processing, so SO2 is often added to prevent browning and to make a bleaching effect.

That’s why you will see the item of SO2 content in the specification of both konjac gum and konjac glucomannan.

The dried konjac needs to be further processed into konjac flour to be used as food raw materials. The quality of the konjac flour primarily depends on the source of the konjac plant.

Components

The glucomannan is the main component in konjac tuber in a dry basis, the assay of which is about 30%-50%, and varies according to the types of konjac, and the rest are cellulose, starch, protein, soluble sugars, inorganic salts, alkaloids, vitamins and etc.

What is Konjac flour?

It is a general name for konjac powder, which can refer to both konjac gum and konjac glucomannan. Both konjac gum and konjac glucomannan (KGM) are derived from konjac flour.

Types of konjac flour

Konjac flour is made from the grinding of slices/chips of dried konjac. According to the purification of glucomannan, it can be classified into three types: common konjac flour, konjac gum and konjac glucomannan.

The color of konjac flour is an important item for judging the quality of konjac flour. The more white the color, the more the content of glucomannan in it.

1. Common konjac flour

Here means unpurified konjac flour and with the following properties:

- Smell: with the inherent smell of konjac and a slight smell of sulfur dioxide.

- Appearance: white, with a small amount of yellow, brown or black particles.

- Purity: a very simple purification process to remove starch and cellulose.

- Glucomannan content: not less than 65%.

- Viscosity: ≥ 14,000 mpa.s

- Mesh size: commonly with 40-120mesh and above 120mesh in the market.

2. Konjac gum

Also known as purified konjac flour, obtained by aqueous extraction of konjac flour. It is not claimed as dietary fiber and so without physiological benefits.

- Smell: with the inherent smell of konjac.

- Appearance: white to cream to light tan powder.

- Glucomannan content: not less than 75%.

- Viscosity: ≥ 23,000 mpa.s.

3. Konjac Glucomannan

Konjac glucomannan (KGM) is a natural food gum extracted from the hemicellulose component in the cell walls of Amorphophallus konjac. It is also a water-soluble dietary fiber.

KGM is a natural high-molecular-weight polysaccharide, with excellent hydrophilicity, gelability, emulsification, film-forming and thickening effect.

Due to these properties, KGM has a wide range of applications in food.

Manufacturing process

Glucomannan is produced by washing konjac flour with water-containing ethanol as it is easy to absorb water and insoluble in ethanol.

The ethanol precipitation manufacturing process is to isolate glucomannan by removing starches, cellulose, protein and other components. And follows centrifugation, milled, drying and other processes to obtain pure KGM.

Structure

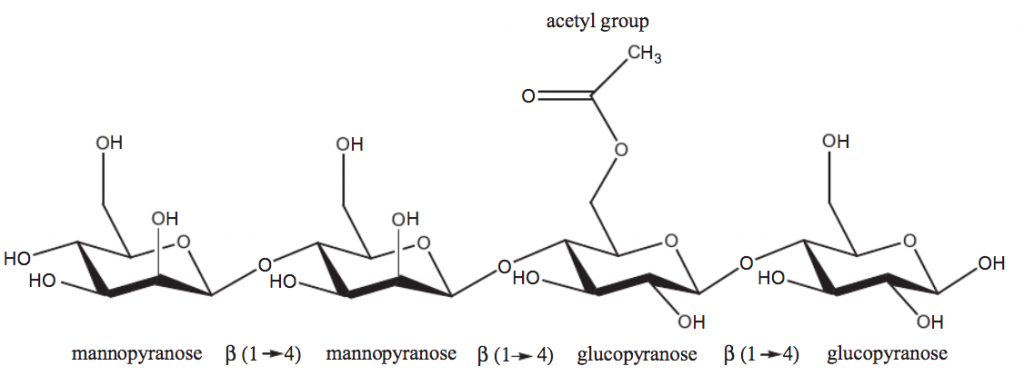

Glucomannan is composed of D-mannose and D-glucose units at a molar ratio of 1.6:1.0, connected by b(1-4)-glycosidic bonds.

Chemical Structure of Repeating unit, Source

Specification

| Other names |

|

| CAS number | 37220-17-0 |

| Chemical formula | C24H42O21 (Glucomannan) |

| Molecular weight | 200,000–2,000,000 (konjac gum)

500,000–2,000,000 (konjac glucomannan) |

Properties

Solubility

The large molecular weight lowers the solubility of konjac in water, but the presence of a large number of hydroxyl groups in the molecule enables it to absorb around 80-100 times a quantity of their own.

Viscosity

Highest viscosity

Konjac forms highly viscous solutions after swells and hydrates in water. The viscosity of 1g konjac dissolved in 100g water can produce 20,000cps to 40,000cps, which is the highest viscosity among thickeners at the same concentration, such as carrageenan, xanthan gum and gum arabic.

Compared with thickeners such as guar gum, xanthan gum, and locust bean gum, konjac is a nonionic polysaccharide and less affected by salt ions (calcium, potassium or sodium ions) in viscosity and gel structure.

The high viscosity enables it can be used as a thickening agent in sauces, soups and dressings.

Synergy

A good synergistic thickening effect with other thickeners, such as xanthan gum and starch. The solution viscosity can increase 2 to 3 times if 1% xanthan gum is combined with 0.02% to 0.03% konjac. The viscosity of the solution mixture of 4.5% modified corn starch with 0.5% konjac is 4-9 times higher than that of 4.5% modified corn starch. Therefore, the quantity of other thickeners can be reduced if with konjac in food.

Gel

Thermally irreversible gel

Konjac can form a thermally irreversible gel in an alkaline condition(e.g. Calcium hydroxide). The water gelling degree depends on the presence of acetyl groups in its molecule.

Gels are formed due to the removal of acetyl groups with alkali and heat. Such gel is thermal stable, even if repeatedly heated at 100 ℃, which is also acid and salt stable.

This property is used to produce calorie-free noodles (shirataki), tofu, rice, pudding and so on, and the flavor can be encapsulated into these kinds of konjac products.

Thermally reversible gel

The thermally reversible gel can be formed when heat the solution combinations of konjac with xanthan gum, gellan gum, carrageenan or other hydrocolloids. It is due to the synergetic effect of gelling.

What’re the Uses of Konjac?

Konjac is commonly used as a gelling agent to produce heat-stable and thermally-reversible gelled foods as follows:

- Pastas

- Noodles

- Prepared meals

- Jellies

- Jams

Konjac also functions as a thickener and stabilizer in bread, cakes, meat products, ice cream and beverages.

Meat

Konjac is as a binder in meat with the properties of thickening, emulsification, water retention and gelling. Meanwhile, it is often used as a fat substitute, e.g. sausage and ham. It enhances water holding capacity, improves meat texture and reduces the fat content.

Starch products

Konjac improves the gelatinization, rheological and texture properties of starch by crosslinking, agglomeration and other reactions with starch. These properties are closely related to the texture, taste and quality of the food. The blends of starch and konjac have a better thickening effect and stability. Meanwhile, the gel formed by the mixture has lower hardness and elasticity.

Adding konjac to convenient rice improves the mouthfeel, makes it tastes closer to fresh rice.

Health benefits

Konjac glucomannan is a nondigestible carbohydrate that was listed as a dietary fiber by the FDA on Jan 10, 2020 (1). Dietary fiber has health benefits as follows: (2):

- Lowering blood glucose/blood pressure/cholesterol levels

- Improving laxation

- Reducing energy intake

Consumption of glucomannan also helps lose weight. (3)

Is Konjac Safe to Eat?

Yes, it is a natural ingredient and almost has no side effects. Its safety has been approved by the U.S. Food and Drug Administration (FDA) and European Food Safety Authority (EFSA), as well as the Joint FAO/WHO Expert Committee on Food Additives (JECFA).

FDA

Konjac flour when used as a food additive is considered GRAS (generally recognized as safe) by the FDA (4).

EFSA

Konjac gum (E 425 i) and konjac glucomannan (E 425 ii) are listed in Commission Regulation (EU) No 231/2012 as an authorised food additive and categorized in “ additives other than colours and sweeteners” (5). Their applications are listed in “Group I” with the maximum level “10 g/kg”. (6)

Safety re-evaluation in 2017

After the studies of carcinogenicity, genotoxicity and other researches, EFSA concluded that there was no need for a numerical acceptable daily intake (ADI) for the uses of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) as food additives and no safety concern under the use of 10 g/kg. (7)

JECFA

Both konjac gum and konjac glucomannan are categorized as konjac flour by JECFA that functions as an emulsifier, gelling agent, stabilizer, thickener. (8)

Acceptable daily intake: ADI “not specific” set in 1996. (9)

Conclusion

Now you may have a knowledge of the thickener & gelling agent – konjac (E425), from the following aspects:

- Konjac products: konjac flour, gum and glucomannan

- Property: solubility, viscosity, gel

- Food uses

- Glucomannan health benefit

- Safety

What kinds of food labels have you found konjac in, feel free to let me know in the comments.

Featured image source