What is Agar Agar (E406) in Food: Source, Types, Uses and Safety

Agar agar, or simply called agar, is a hydrocolloid generally made from Gelidium and Gracilaria, commonly used as a gelling agent and thickener in food. The European food additive number for it is E406. It is the first used phycocolloid with a history of 300 years, much earlier than alginates and carrageenan, which also are extracted from marine algae seaweed.

In this article, we’ll take an overview look at this ingredient and provide you with several resources that’ll give you a broader understanding of it.

Let’s dip into:

- What is agar agar

- Composition

- Manufacturing process

- Four types

- Specification

- Property

- Uses

- Approved Safety

- Possible side effects

- FAQs

- Conclusion

What is Agar Agar?

Definition

By FDA’s definition, Agar-agar is a dried, hydrophilic, colloidal polysaccharide extracted from one of a number of related species of red algae (class Rhodophyceae). (1)

What is it used for?

The main purpose of using agar in food with its following three advantages:

- A natural ingredient, suitable for vegetarians to replace gelatine derived from animal skin and bones.

- The high gelling hysteresis between the gelling and melting temperatures.

- Gel reversibility

Where does it come from?

Agar is a structural carbohydrate existing in the cell walls of agarophyte algae.

What is it made from?

From the above FDA’s definition, we can know it is obtained from the red algae of the class Rhodophyceae. In general, these algae belong to Gelidium and Gracilaria, both are the principal seaweeds for commercially producing agar. These agar seaweeds are also called agarophytes.

1. Gelidium

It grows best at 15-20°C, difficult to cultivate and most harvested naturally in Spain, Portugal, Morocco, Japan and Mexico. Strong-gelling agar can be extracted directly from it.

It is the preferred seaweed source for making bacteriological and pharmaceutical grade agar and agarose.

2. Gracilariaceae

A good plant source for producing food grade agar. Temperatures of 20°C or higher are requested for at least three months of the year for its growth. (2)

It is cultivated on a commercial scale, such as in Chile, Argentina, Brazil, Indonesia, China, the Philippines, and Vietnam.

Once these species were considered low quality due to the strength of a gel it forms. But later, manufacturers finding this property can be improved with alkali treatment to remove the sulfates.

What is Agar Agar made of?

It is a polysaccharide, consisting primarily of D- and L-galactose units. About every tenth D-galactopyranose unit contains a sulfate ester group. Calcium, magnesium, potassium or sodium cations are also associated with the polysaccharide. (3)

It is a complex mixture of polysaccharides, not only consists of two major polysaccharides, agarose and agaropectin, but also with other varieties, some are rich in sulfate, others in pyruvate.

Its composition depends on the sources of seaweed and the production process employed.

1. Agarose

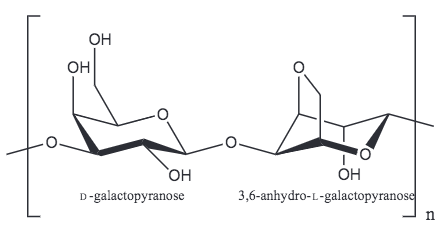

The major component of agar, around 70% or more of its total weight. It provides the gelling power and is free of sulfates. Agarose is made up of the repeating unit of agarobiose, which is a disaccharide, composed of D-galactose and 3–6,anhydro- L-galactose, contributing to the main structure of agar.

The following is the agarobiose structure:

Image Source

2. Agaropectin

The non-gelling fraction, a charged sulfated polysaccharide that will influence solution properties, gel strength and gel features.

How is Agar Agar made?

In general, the manufacturing process of agar powder has the following steps:

- Algae harvesting: agar plants mature in summer.

- Preliminary drying: the moisture content can be reduced around 80% by natural or artificial dehydration.

- Bleaching: sodium hypochlorite and/or H2O2 are used.

- Extraction: after this process, agar is dissolved in boiling water. This process may be different depending on the type of agarophyte and the product quality needed. Gelidium is processed under pressure (105–110°C for 2–4 h) and Gracilaria is usually treated with water at 95–100°C for 2–4 h.

- Before the extraction, alkaline treatment (with sodium hydroxide) is usually employed for Gracilaria to hydrolyze the sulfates and so the agar gel-forming ability increased. Otherwise, the gel strength is too low for commercial use.

- Rest steps: filtration, gelling and freezing/thawing, drying, milling and packing.

Four types of Agar Agar

According to the different appearance and application, food grade agar in the market can be classified into 4 types. Respectively bar, strip (string), flake and powder.

Agar powder is mostly used for industrial applications. Flakes, bars and strips are mostly used in cooking. (4)

Strips and Bars

Strips and bars are the old forms which are manufactured through a more traditional production method by freezing and thawing the agar gel. Sometimes they are called natural agar.

The gels are cut into square bars or extruded to produce spaghetti-like strips 25–40 cm long after cooling down. These two types are produced mostly from Gelidium and commonly used at home to prepare traditional dishes. (Handbook of hydrocolloids, Edited by G. O. Phillips and P. A. Williams, 2000)

Before cooking, these two forms need to soak before soften, and then put in boiled water to make it completely dissolved. Later add other ingredients, such as sweeteners, colors, flavours, or fruits to make the recipes.

Flakes and Powder

Flakes and powder are smaller size ones that can quickly dissolve in boiling water. Soaking may be needed for flakes before cooking. The powdered form is the most used one.

Specification

| Other names | Agar, Gelose, Kanten, Ceylon, Chinese or Japanese isinglass |

| CAS number | 9002-18-0 |

| Chemical formula | NA |

| Molecular weight | NA |

| Appearance | Agar powder is white to yellowish-white or pale yellow, odorless or has a slight characteristic odour. |

Property

Solubility

Insoluble in cold water; soluble in boiling water.

Gelation

Gel strength comes from the composition of agarose.

How to form a Gel

Heat is required to make agar completely soluble and the solution will gel upon cooling. Unlike carrageenan, it does not require the presence of any particular ions to gel. Also, it is different with high methoxyl pectin, the gel of which depending on sugar.

Low concentration is needed

It absorbs 20 times of water and swells in cold water. When dissolved in hot water and upon cool, it solidifies at a very low concentration (0.5%). But it cannot be gelled and will become a viscous liquid if the concentration is below 0.1%.

Setting and melting point

1% agar solution solidifies at 32 ~ 42 °C, its gel has elasticity, and its melting point is 80 ~ 96 °C. Many of its uses take advantage of this large difference between gelling and melting temperature.

When compared with gelatin gels, it is tasteless, odorless, and sets more firmly, even at room temperature. Gelatin gels melt around 35-40 °C.

Reversibility

Agarose produces ‘physical gels’ which means the gel formed only by hydrogen bonds which make the gel reversible. That’s to say, it melts just by heating but gels again upon cooling. These transformations can be repeated. The reversibility is an important property of agar gel. Gelatin also has the same characteristics. This advantage can be used in a lot of applications, such as in food, microbiology, biochemistry and so on.

On the contrary, the ‘chemical gels’ is taken place by covalent bonds which can be considered through a chemical reaction and shape the gel irreversible.

Synergies

Agar obtained from Gelidium is synergistic with locust bean gum (LBG) due to the agaropectin in Gelidium. The increased gel strength, decreased rigidity and enhanced elasticity are observed in the gel formed by the mixture of LBG and Gelidium agar.

Agar comes from Gracilaria shows synergy with sugar, resulting in an increased gel strength when used in high sugar concentration (around 60%) products, such as jams and jellies. (Handbook of hydrocolloids, Edited by G. O. Phillips and P. A. Williams, 2000)

What are the uses of Agar Agar?

This hydrocolloid is primarily used for its gelling properties. About 90% in the market is used in food applications, with the remaining 10% is intended for bacteriological and other biotechnology applications. (5)

Food

Generally, agar is used in jelly, bakery, confectionery, dairy products, beverage, meat products and so on.

Jelly

The most use of agar is in jellies and other desserts that need to gel.

In Asian countries, agar is a traditional and popular component of jellies. For producing jellies and puddings, agar is boiled in water first, making it completely soluble, then add colors, flavors, sweeteners and fruits to the liquid before cooled and finally pour the liquid mix into molds to form a jelly.

Bakery

In the baking process, it stabilizes and thickens pie fillings, sugar icings, bread dough, cake glazes, coatings and meringues with the property of withstanding high temperature.

Confectionery

Nowadays, agar from Gracilaria is often used in confectionery with high sugar content, such as fruit candies, gummies, gums, caramels, marshmallows and etc.

Dairy Products

Agar can be used in dairy products like yogurts, ice cream, cheese, chocolate and etc.

Beverage

It acts as a clarifying and refining agent for juices, beers and wines.

Meat Products

Agar is also used to gel meat and fish products, and function as a gelatin substitute for its higher melting temperature and gel strength.

Cosmetics

Per “European Commission database for information on cosmetic substances and ingredients”, it can function as binding, masking and viscosity controlling agents in cosmetic and personal care products. (6)

Pharmaceuticals

It is soluble dietary fiber and has the health benefits used as a mild laxative in the treatment of malfunctions of the digestive tract for its swelling properties.

Others

Agar is used as a solidifying agent in bacteriological culture media.

Is Agar Agar safe to eat?

Yes, it almost has no side effects and the safety has been approved by the U.S. Food and Drug Administration (FDA) and European Food Safety Authority (EFSA), as well as the Joint FAO/WHO Expert Committee on Food Additives (JECFA).

FDA

It is GENERALLY RECOGNIZED AS SAFE (GRAS) and can be used as an emulsifier or emulsifier salt, flavor enhancer, processing aid, stabilizer or thickener, surface-finishing agent and texturizer in food. (7)

The following food may have it and with the approved maximum use levels (8):

- Baked goods and baking mixes: 0.8%

- Confections and frostings: 2.0%

- Soft candy: 1.2%

- All other food categories: 0.25%

EFSA

Agar Agar (E 406) is authorised as a food additive in the European Union (EU) in accordance with Annex II and Annex III to Regulation (EC) No 1333/2008 on food additives and categorized as “additives other than colours and sweeteners” (9)

Safety re-evaluation in 2016

After the study of genotoxicity, carcinogenicity, reproductive, developmental toxicity and so on, EFSA concluded that “no need for a numerical ADI for agar, and that there is no safety concern for the general population at the refined exposure assessment for the reported uses of agar as food additive.” (10)

Uses

Its approved applications are listed separately with E406 or in Group I where the uses is quantum satis (QS).

Following foods may contain it (11):

- Unflavoured live fermented cream products and substitute products

- Jam, jellies and marmalades and sweetened chestnut purée

- fruit or vegetable spreads

- Dietary foods for special medical purposes

UK Food Standards Agency

Categorized as an emulsifier, stabiliser, thickener and gelling agent. (12)

Food Standards Australia New Zealand

It is an approved ingredient in Australia and New Zealand with the code number 406. (13)

JECFA (Joint FAO/WHO Expert Committee on Food Additives)

Function Class: food additives, emulsifier, stabilizer, thickener. (14)

Acceptable daily intake (ADI): “not limited” set since 1973. (15)

What Are The Possible Side Effects of Agar Agar?

It is common that sometimes consumers have questions whether agar is bad for our health and what are the side effects. We understand that consumers have concerns about ingredients in the foods we eat. However, there are few reports concerns the health risk of agar. Maybe someone will be allergic to it.

Allergy

According to the information provided by EFSA in 2016, that:

- A 64-year-old woman with a gastric bypass for morbid obesity experienced nausea, vomiting and dysphagia after intaking an agar-based dessert.

- A 70-year-old Japanese woman experienced abdominal pain, nausea and vomiting after eating a large amount of highly concentrated agar.

Frequently asked questions

Is it Natural?

Yes, agar is natural as it is a naturally occurring material in red algae (class Rhodophyceae).

Is it Halal?

Yes, it is halal complying with the policy of Muslim. And we can find several suppliers certificated with MUI halal.

Is it Kosher?

Yes, it is kosher pareve. It has met all the “kashruth” requirements and can be certified as kosher.

Is it Gluten free?

Yes, it is gluten free according to FDA that agar does not contain wheat, rye, barley, or crossbreeds of these grains. (16)

Is it Vegan?

Yes, it is vegan. Raw materials and the manufacturing process without the use of animal matter or products derived from animal origin. That makes it suitable for vegetarian and vegan diets, often used as meat substitutes and gelatin replacement.

Is Agar Edible?

The food grade is edible. Maybe you’re thinking the agar in bacteriological culture media is edible. They’re two grades.

How to use Agar?

Normally agar needs to dissolve in boiling water before its use. In some food applications, agar is usually premixed with sugar, later adding the blends slowly to water to avoid clumps that can form during dispersion.

Conclusion

Now you may have a knowledge of the thickener and gelling agent – Agar agar (E406), from the following aspects:

- Composition: agarose and agaropectin

- Manufacturing processes

- Four types in the market: strips, bars, flakes and powder

- Uses in food

- Safety

- Side effects

- FAQs

What kinds of food labels have you found this ingredient in? Did I miss anything and what do you think of this ingredient? Let me know in the comments.

Hello, I was reading your article about Agar Agar and I was hoping to find some information regarding the strength of it. Are you able to tell me whether the strength of the powdered Agar Agar is the same as the strips? For example, is 1g of the powdered Agar Agar same as 1g of strips. I have read somewhere that the powdered form is stronger and you need to double in size, however, the measure form was in teaspoons and cups, which is very inaccurate. Does anything changes or removed in the process of Agar Agar made into powder. I have baked with powdered Agar Agar before but have purchased the strips and unfortunately, the deserts do not set. Many thanks.

Does anyone know what is the difference between the manufacturing process of Food-grade agar and cultural media agar and what is the difference in their composition?